|

| October 11, 2016 | Volume 12 Issue 38 |

Motion Control News & Products

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Overhung load adaptors provide load support and contamination protection

Overhung load adaptors (OHLA) provide both overhung radial and axial load support to protect electrified mobile equipment motors from heavy application loads, extending the lifetime of the motor and alleviating the cost of downtime both from maintenance costs and loss of production. They seal out dirt, grime, and other contaminants too. Zero-Max OHLAs are available in an extensive offering of standard models (including Extra-Duty options) for typical applications or customized designs.

Overhung load adaptors (OHLA) provide both overhung radial and axial load support to protect electrified mobile equipment motors from heavy application loads, extending the lifetime of the motor and alleviating the cost of downtime both from maintenance costs and loss of production. They seal out dirt, grime, and other contaminants too. Zero-Max OHLAs are available in an extensive offering of standard models (including Extra-Duty options) for typical applications or customized designs.

Learn more.

Why choose electric for linear actuators?

Tolomatic has been delivering a new type of linear motion technology that is giving hydraulics a run for its money. Learn the benefits of electric linear motion systems, the iceberg principle showing total cost of ownership, critical parameters of sizing, and conversion tips.

Tolomatic has been delivering a new type of linear motion technology that is giving hydraulics a run for its money. Learn the benefits of electric linear motion systems, the iceberg principle showing total cost of ownership, critical parameters of sizing, and conversion tips.

Get this informative e-book. (No registration required)

New AC hypoid inverter-duty gearmotors

Bodine Electric Company introduces 12 new AC inverter-duty hypoid hollow shaft gearmotors. These type 42R-25H2 and 42R-30H3 drives combine an all-new AC inverter-duty, 230/460-VAC motor with two hypoid gearheads. When used with an AC inverter (VFD) control, these units deliver maintenance-free and reliable high-torque output. They are ideal for conveyors, gates, packaging, and other industrial automation equipment that demands both high torque and low power consumption from the driving gearmotor.

Bodine Electric Company introduces 12 new AC inverter-duty hypoid hollow shaft gearmotors. These type 42R-25H2 and 42R-30H3 drives combine an all-new AC inverter-duty, 230/460-VAC motor with two hypoid gearheads. When used with an AC inverter (VFD) control, these units deliver maintenance-free and reliable high-torque output. They are ideal for conveyors, gates, packaging, and other industrial automation equipment that demands both high torque and low power consumption from the driving gearmotor.

Learn more.

Next-gen warehouse automation: Siemens, Universal Robots, and Zivid partner up

Universal Robots, Siemens, and Zivid have created a new solution combining UR's cobot arms with Siemens' SIMATIC Robot Pick AI software and Zivid's 3D sensors to create a deep-learning picking solution for warehouse automation and intra-logistics fulfillment. It works regardless of object shape, size, opacity, or transparency and is a significant leap in solving the complex challenges faced by the logistics and e-commerce sectors.

Universal Robots, Siemens, and Zivid have created a new solution combining UR's cobot arms with Siemens' SIMATIC Robot Pick AI software and Zivid's 3D sensors to create a deep-learning picking solution for warehouse automation and intra-logistics fulfillment. It works regardless of object shape, size, opacity, or transparency and is a significant leap in solving the complex challenges faced by the logistics and e-commerce sectors.

Read the full article.

Innovative DuoDrive gear and motor unit is UL/CSA certified

The DuoDrive integrated gear unit and motor from NORD DRIVE-SYSTEMS is a compact, high-efficiency

solution engineered for users in the fields of intralogistics, pharmaceutical, and the food and beverage industries. This drive combines a IE5+ synchronous motor and single-stage helical gear unit into one compact housing with a smooth, easy-to-clean surface. It has a system efficiency up to 92% and is available in two case sizes with a power range of 0.5 to 4.0 hp.

The DuoDrive integrated gear unit and motor from NORD DRIVE-SYSTEMS is a compact, high-efficiency

solution engineered for users in the fields of intralogistics, pharmaceutical, and the food and beverage industries. This drive combines a IE5+ synchronous motor and single-stage helical gear unit into one compact housing with a smooth, easy-to-clean surface. It has a system efficiency up to 92% and is available in two case sizes with a power range of 0.5 to 4.0 hp.

Learn more.

BLDC flat motor with high output torque and speed reduction

Portescap's 60ECF brushless DC slotted flat motor is the newest frame size to join its flat motor portfolio. This 60-mm BLDC motor features a 38.2-mm body length and an outer-rotor slotted configuration with an open-body design, allowing it to deliver improved heat management in a compact package. Combined with Portescap gearheads, it delivers extremely high output torque and speed reduction. Available in both sensored and sensorless options. A great choice for applications such as electric grippers and exoskeletons, eVTOLs, and surgical robots.

Portescap's 60ECF brushless DC slotted flat motor is the newest frame size to join its flat motor portfolio. This 60-mm BLDC motor features a 38.2-mm body length and an outer-rotor slotted configuration with an open-body design, allowing it to deliver improved heat management in a compact package. Combined with Portescap gearheads, it delivers extremely high output torque and speed reduction. Available in both sensored and sensorless options. A great choice for applications such as electric grippers and exoskeletons, eVTOLs, and surgical robots.

Learn more and view all the specs.

Application story: Complete gearbox and coupling assembly for actuator system

Learn how GAM engineers not only sized and selected the appropriate gear reducers and couplings required to drive two ball screws in unison using a single motor, but how they also designed the mounting adapters necessary to complete the system. One-stop shopping eliminated unnecessary components and resulted in a 15% reduction in system cost.

Learn how GAM engineers not only sized and selected the appropriate gear reducers and couplings required to drive two ball screws in unison using a single motor, but how they also designed the mounting adapters necessary to complete the system. One-stop shopping eliminated unnecessary components and resulted in a 15% reduction in system cost.

Read this informative GAM blog.

Next-gen motor for pump and fan applications

The next evolution of the award-winning Aircore EC motor from Infinitum is a high-efficiency system designed to power commercial and industrial applications such as HVAC fans, pumps, and data centers with less energy consumption, reduced emissions, and reduced waste. It features an integrated variable frequency drive and delivers upward of 93% system efficiency, as well as class-leading power and torque density in a low-footprint package that is 20% lighter than the previous version. Four sizes available.

The next evolution of the award-winning Aircore EC motor from Infinitum is a high-efficiency system designed to power commercial and industrial applications such as HVAC fans, pumps, and data centers with less energy consumption, reduced emissions, and reduced waste. It features an integrated variable frequency drive and delivers upward of 93% system efficiency, as well as class-leading power and torque density in a low-footprint package that is 20% lighter than the previous version. Four sizes available.

Learn more.

Telescoping linear actuators for space-constrained applications

Rollon's new TLS telescoping linear actuators enable long stroke lengths with minimal closed lengths, which is especially good for applications with minimal vertical clearance. These actuators integrate seamlessly into multi-axis systems and are available in two- or three-stage versions. Equipped with a built-in automated lubrication system, the TLS Series features a synchronized drive system, requiring only a single motor to achieve motion. Four sizes (100, 230, 280, and 360) with up to 3,000-mm stroke length.

Rollon's new TLS telescoping linear actuators enable long stroke lengths with minimal closed lengths, which is especially good for applications with minimal vertical clearance. These actuators integrate seamlessly into multi-axis systems and are available in two- or three-stage versions. Equipped with a built-in automated lubrication system, the TLS Series features a synchronized drive system, requiring only a single motor to achieve motion. Four sizes (100, 230, 280, and 360) with up to 3,000-mm stroke length.

Learn more.

Competitively priced long-stroke parallel gripper

The DHPL from Festo is a new generation of pneumatic long-stroke grippers that offers a host of advantages for high-load and high-torque applications. It is interchangeable with competitive long-stroke grippers and provides the added benefits of lighter weight, higher precision, and no maintenance. It is ideal for gripping larger items, including stacking boxes, gripping shaped parts, and keeping bags open. It has high repetition accuracy due to three rugged guide rods and a rack-and-pinion design.

The DHPL from Festo is a new generation of pneumatic long-stroke grippers that offers a host of advantages for high-load and high-torque applications. It is interchangeable with competitive long-stroke grippers and provides the added benefits of lighter weight, higher precision, and no maintenance. It is ideal for gripping larger items, including stacking boxes, gripping shaped parts, and keeping bags open. It has high repetition accuracy due to three rugged guide rods and a rack-and-pinion design.

Learn more.

Extend your range of motion: Controllers for mini motors

FAULHABER has added another extremely compact Motion Controller without housing to its product range. The new MC3603 controller is ideal for integration in equipment manufacturing and medical tech applications. With 36 V and 3 A (peak current 9 A), it covers the power range up to 100 W and is suitable for DC motors with encoder, brushless drives, or linear motors.

FAULHABER has added another extremely compact Motion Controller without housing to its product range. The new MC3603 controller is ideal for integration in equipment manufacturing and medical tech applications. With 36 V and 3 A (peak current 9 A), it covers the power range up to 100 W and is suitable for DC motors with encoder, brushless drives, or linear motors.

Learn more.

When is a frameless brushless DC motor the right choice?

Frameless BLDC motors fit easily into small, compact machines that require high precision, high torque, and high efficiency, such as robotic applications where a mix of low weight and inertia is critical. Learn from the experts at SDP/SI how these motors can replace heavier, less efficient hydraulic components by decreasing operating and maintenance costs. These motors are also more environmentally friendly than others.

Frameless BLDC motors fit easily into small, compact machines that require high precision, high torque, and high efficiency, such as robotic applications where a mix of low weight and inertia is critical. Learn from the experts at SDP/SI how these motors can replace heavier, less efficient hydraulic components by decreasing operating and maintenance costs. These motors are also more environmentally friendly than others.

View the video.

Tiny and smart: Step motor with closed-loop control

Nanotec's new PD1-C step motor features an integrated controller and absolute encoder with closed-loop control. With a flange size of merely 28 mm (NEMA 11), this compact motor reaches a max holding torque of 18 Ncm and a peak current of 3 A. Three motor versions are available: IP20 protection, IP65 protection, and a motor with open housing that can be modified with custom connectors. Ideal for applications with space constraints, effectively reducing both wiring complexity and installation costs.

Nanotec's new PD1-C step motor features an integrated controller and absolute encoder with closed-loop control. With a flange size of merely 28 mm (NEMA 11), this compact motor reaches a max holding torque of 18 Ncm and a peak current of 3 A. Three motor versions are available: IP20 protection, IP65 protection, and a motor with open housing that can be modified with custom connectors. Ideal for applications with space constraints, effectively reducing both wiring complexity and installation costs.

Learn more.

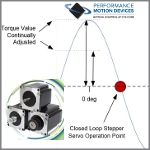

Closed loop steppers drive new motion control applications

According to the motion experts at Performance Motion Devices, when it comes to step motors, the drive technique called closed loop stepper is making everything old new again and driving a burst of interest in the use of two-phase step motors. It's "winning back machine designers who may have relegated step motors to the category of low cost but low performance."

According to the motion experts at Performance Motion Devices, when it comes to step motors, the drive technique called closed loop stepper is making everything old new again and driving a burst of interest in the use of two-phase step motors. It's "winning back machine designers who may have relegated step motors to the category of low cost but low performance."

Read this informative Performance Motion Devices article.

Intelligent compact drives with extended fieldbus options

The intelligent PD6 compact drives from Nanotec are now available with Profinet and EtherNet/IP. They combine motor, controller, and encoder in a space-saving package. With its 80-mm flange and a rated power of 942 W, the PD6-EB is the most powerful brushless DC motor of this product family. The stepper motor version has an 86-mm flange (NEMA 34) and a holding torque up to 10 Nm. Features include acceleration feed forward and jerk-limited ramps. Reduced installation time and wiring make the PD6 series a highly profitable choice for machine tools, packaging machines, or conveyor belts.

The intelligent PD6 compact drives from Nanotec are now available with Profinet and EtherNet/IP. They combine motor, controller, and encoder in a space-saving package. With its 80-mm flange and a rated power of 942 W, the PD6-EB is the most powerful brushless DC motor of this product family. The stepper motor version has an 86-mm flange (NEMA 34) and a holding torque up to 10 Nm. Features include acceleration feed forward and jerk-limited ramps. Reduced installation time and wiring make the PD6 series a highly profitable choice for machine tools, packaging machines, or conveyor belts.

Learn more.

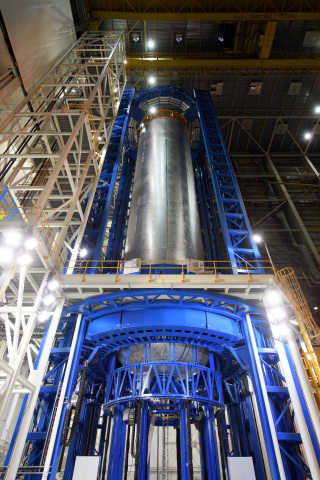

Summer of testing concludes for NASA's journey to Mars

NASA and the agency's industry team for the Space Launch System (SLS) rocket and the Orion spacecraft are concluding a successful summer of testing in preparation for the first integrated flight. The uncrewed, three-week mission, currently designated Exploration Mission-1 (EM-1), is scheduled for late 2018. During the mission, SLS will send Orion about 40,000 miles beyond the moon during a flight that will be farther from Earth than any spacecraft built to carry humans has ever traveled.

"A rigorous flight test program is critical to ensuring all systems are ready for the journey," said Tony Antonelli, Lockheed Martin's chief technologist for civil space exploration programs. "Crew safety is the highest priority as NASA prepares to send astronauts into deep space and eventually Mars."

In June, Orbital ATK concluded full-scale solid rocket booster qualification testing at their facility in Promontory, UT, that blasted 3.6 million lb of thrust during the 2-min. test -- burning approximately 1.4 million lb of propellant at an average of 5.5 tons per second. The SLS boosters and all data to date show the motors performed as expected. Two five-segment boosters will provide initial thrust to boost the SLS and Orion off the launch pad and during its first 2+ min. of flight.

The Orbital ATK-manufactured, full-scale solid rocket booster qualification test in June.

Four Aerojet Rocketdyne RS-25 engines will provide thrust to the core stage during SLS launch and ascent. In July and August, the company conducted tests on the RS-25 development engine 0528 at NASA's Stennis Space Center in Mississippi. After testing this summer, RS-25 engine 0528 has accumulated 99 starts and 54,572 sec of hotfire time, including 1,263 sec of test time dedicated to SLS development. These state-of-the-art engines will operate for a full 8 1/2 min. to help boost Orion into orbit.

The RS-25 rocket engine built by Aerojet Rocketdyne is tested for 420 sec at NASA's Stennis Space Center on Aug. 18, 2016. [Photo courtesy: NASA]

Data from this summer, combined with earlier test data, indicate the RS-25 engines will exceed SLS mission requirements. Each engine produces more than 500,000 lb of thrust.

Boeing, building the core stages in New Orleans, completed welding on the liquid hydrogen tank flight and qualification test articles in the world's largest welding tool. The tank is part of the core stage, which accounts for the largest section of the rocket at more than 200 ft in height. The qualification tank is being readied at NASA's Michoud Assembly Facility in Louisiana for barge transport to NASA's Marshal Space Flight Center in Huntsville for structural loads testing.

Boeing completes welding on a liquid hydrogen fuel tank for the SLS core stage for EM-1 mission.

As other qualification test elements of the core stage are completed, they will be shipped to NASA's Marshall Space Flight Center (MSFC), where the core stage will be assembled for full-up qualification structural loads testing of the massive structure. NASA is completing construction of the tank test stands this fall at MSFC. In addition, NASA accepted delivery of the interim cryogenic propulsion stage test article at MSFC for testing later this year.

"As NASA readies for the next stage of testing, flight hardware for the first mission is in production for both the core stage and the interim cryogenic propulsion stage," added Jacqueline Nesselroad, director of Boeing operations at Michoud.

On the Orion program, Lockheed Martin engineering teams recently finished proof pressure testing of the EM-1 crew module at Kennedy Space Center in Florida, a critical milestone in certifying the structural integrity of the vehicle for its next mission. At the same time, engineers are conducting a series of critical acoustic and vibration tests for the service module at NASA Glenn's Plum Brook Station in Sandusky, OH.

Lockheed Martin engineers and technicians prepare the Orion pressure vessel for a series of tests inside the proof pressure cell in the Neil Armstrong Operations and Checkout Building at NASA's Kennedy Space Center in Florida.

In August, the Aerojet Rocketdyne-manufactured jettison motor for Orion's Launch Abort System successfully test fired 45,000 lb of thrust at the company's Sacramento facility. In keeping with the approach of "testing like you fly," water impact tests have been conducted by NASA and Lockheed Martin at the agency's Langley Research Center in Hampton, VA. These tests study the effects that various water-landing impacts will have on the crew to ensure engineers understand splashdown scenarios after the space flight.

Another critical element in ensuring crew safety is Orion's entry parachute system. The parachutes will slow the capsule down from its high-speed re-entry of 25,000 mph to a relatively gentle 20 mph for splashdown. This fall, the parachute team is beginning qualification tests of the system for human flights, encompassing eight integrated drop tests that will simulate a variety of landing scenarios.

"All of this testing adds up to lowering the risk for astronauts to ensure they arrive and return safely from their destinations," said Julie Van Kleeck, vice president of Advanced Space and Launch at Aerojet Rocketdyne.

Sources: Aerojet Rocketdyne, Boeing, Lockheed Martin, Orbital ATK

Published October 2016

Rate this article

View our terms of use and privacy policy